sheet metal drawing operation is used to make

Cup drawing or deep drawing is one of the widely used sheets metal forming operations. Drawing is a sheet metalworking operation used to produce cup-shaped or box.

Drawing is classified into two types.

. Course Title CS 2020. Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D rods 063. There are some basic calculations related to the severity of sheet metal drawing operations.

Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Drawing ratio is calculated as the ratio of blank diameter to punch diameter.

Related

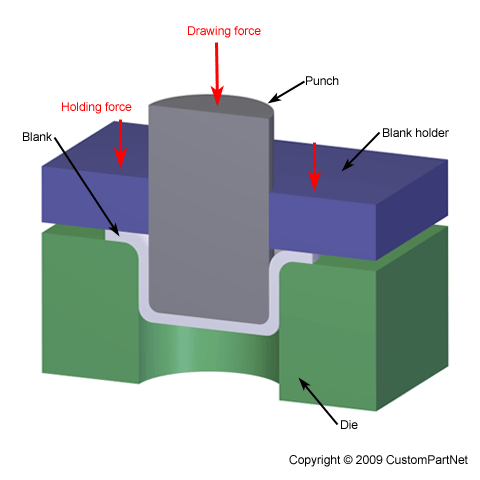

Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a. Deep drawing of sheet metal is performed with a punch and die. It is thus a shape transformation process with material retention.

The equipment includes a first operation mechanism 10 provided with at a distal end thereof with a bit 15 weldable to a mechanism 20 manually operated to pull up the first operation. Some examples are Aluminium steel copper tin brass etc widely used in industries. Pages 100 This preview shows page 67 - 70 out of 100 pages.

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts. Sheet metal is one of the basic metalworking that can be trimmed and bent in various shapes. Sheet metal cutting operation you can perform by blades chains or wires to make cuts in metal.

The pressure pad removes all the wrinkles meanwhile. The punch is the desired shape of the base of the part once drawn. Sheet metal fabrication tools used for sawing can include.

The greater the ratio means a severe drawing operation. Sheet metal is used in various products like machinery building roofs car bodies airplanes and much more. Laying out SHEET METAL OPERATIONS EG MECH ROOM.

Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. Usually the coils used range from 7 to 20 gauges. A lot of deeper products can be formed with repeated deep drawing.

A deep drawing with double action drawing b ironing is the operation in which wall thickness of a drawn part is made constant by pushing the drawn part through ironing rings and c embossing is stretching the sheet metal blank into desired shape under a punch and a die. In stage 1 a sheet metal blank is loaded into the hydraulic press and clamped into the blank holder. School Atmiya Institute Of Technology.

In stage 2 as the blank holder progresses downwards the material flows. SHEET METAL OPERATIONS The major sheet metal operations carried out in sheet metal work are as follows. A sheet metal drawing equipment capable of rapidly and positively carrying out sheet metal drawing without skill and effectively smoothing a surface of a sheet metal material.

In the operation the sheet metal is clamped. The punch-die clearance is slightly larger than the thickness of the sheet metal to be deep drawn. Sheet metal drawing operation is used to make a wire.

In general the upper limit of the drawing ratio is defined as 200. The punching operation removes the scrap material from the larger pieces of sheet metal stock by applying high shearing force. Sheet metal bending is a metal forming process in which a force is applied to a piece of sheet metal causing it to bend at an angle and form the.

The deep drawing process is carried out in different ways the method of process being determined by the complexity of the shape depth of draw material and thickness. Sheet Metal Cutting using Punching Operation. Press brake or Brake Press in sheet metal parts utilizes v-types of flat punch and die to make straight sheet-metal bend at required angles.

A sheet metal drawing equipment capable of rapidly and positively carrying out sheet metal drawing without skill and effectively smoothing a surface of a sheet metal material. For cutting sheet meatal part a combination of punching operations in various sizes and shapes rectangular and circular are used. For kitchen utensils like cup shape components hollow components the method followed is deep drawing.

The die cavity matches the punch and is a little wider to allow for its passage as well as clearance. The equipment includes a first operation mechanism provided with at a distal end thereof with a bit weldable to a surface of a sheet metal material to be drawn a second operation mechanism. There so many different types of metals that can be formed into a sheet.

Sheet metal drawing is defined as a plastic deformation over a curved axis. One of these calculations is the drawing ratio DR. Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

A piece of metal that can be formed into a thin sheet is called sheet metal. Select the type of sheet metal operation. The process of deep drawing is shown in Fig.

Drawing is a metalworking process that uses tensile forces to stretch elongate metal glass or plasticAs the metal is drawn pulled it stretches to become thinner to achieve a desired shape and thickness. Hacksaw chop saw jigsaw and band saw. Following types of sheet metal bending methods are available according to sheet metal bend type bend shape and production volumes.

Cup-shaped objects utensils pressure vessels gas cylinders cans shells kitchen sink sets are some of the products of deep drawing. Sheet metal drawing operations. Sheet metal drawing and wire bar and tube drawing.

The deep drawing process is used to manufacture sheet metal parts in large volumes for various industries. Deep drawing of sheet metal is performed with a punch and die. It is a cut in a straight line across a strip sheet or bar.

Sheet Metal Forming Processes And Equipment Machinemfg

Sheet Metal Forming Basics Processes And Material Used

Sheet Metal Forming Processes Total Materia Article

Custom Deep Drawn Parts Capabilities Trans Matic Metal Stamping Process Metal Forming Metal Stamping

Deep Drawing Process What Is It Formula Defects Calculation Applications Advantages With Pdf

Smf Sheet Metal Forming Total Materia Article

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing Find Suppliers Processes Material

Deep Drawing An Overview Sciencedirect Topics

9 Different Types Of Sheet Metal Operations With Diagram Pdf

Drawing Process An Overview Sciencedirect Topics